by Steve Wolff

The exigencies of WW 1 brought about rapid advances in aircraft design and engine reliability: advances that did not go unnoticed by two visionaries within the Wilson administration. In the fiscal year 1917-1918, Postmaster General Albert Sidney Burleson and Second Assistant Postmaster General Otto Praeger along with a Congressional appropriation of $100,000, embarked on a bold experiment to sponsor the growth of commercial aviation through federal benefice. As a prelude to a national network of airways, a short 218 mile section between Washington D.C. and New York City with a stop at Philadelphia Pennsylvania was selected for trail flights. The beginning was less than auspicious.

On May 15th young Lieutenant George L. Boyle took off from the Polo Grounds, Washington, D.C. for Bustleton airfield, Philadelphia, Pennsylvania, amid much fanfare and hope. Dignified onlookers included President Woodrow Wilson and his wife Edith, Postmaster General Albert S. Burleson and Second Assistant Postmaster General Otto

Praeger. Swooping low over the field with confidence, Boyle and the Curtiss JN-4, carrying several thousand letters, turned north, and then inexplicably south, where Boyle, now hopelessly lost-touched down near Waldorf, Maryland some 25 miles form his stating point, breaking the propeller in the process.[1]

Two days later, given a chance to redeem himself, Lt. Boyle departed again, this time with an escort and having been briefed to keep the Chesapeake Bay shoreline on his right.

Shortly into the flight, engine trouble forced the escort to drop out. Undeterred, Boyle pressed on, discovering that the Delaware River, which he was supposed to follow to Philadelphia, was now on his left. Believing he was following still following the Chesapeake Bay, Boyle did a 180˚ turn and continued to follow the shoreline to Cape Charles, Virginia, where he ran out of gas, land and airspeed simultaneously.[2] All of which served to dramatically underscore the difficulties facing pilots trying to fly cross-country with unreliable compasses and without adequate maps or ground based navigational aids.

For the nest five years, without manmade navigational aids, radios and maps, airmail pilots resorted to “contact” flying by which visual contact was maintained with geographic features such as rivers, shorelines and the “Iron Compass” as railroads were referred to by airmail pilots. By 1921, the U.S. Airmail Service had firmly established itself as a day-time only operation between New York and San Francisco. Sometimes referred to as the “Columbia” or transcontinental route, mail planes were flown to selected points along the railroad where the plane would land in the evening and transfer the mail to a waiting train, which would move the postal cargo further down the line to be picked up in the morning by another aircraft. This ‘leapfrogging’ of the mail across the continent drew the ire of Congressional appropriation committees and the scorn of rail officials, as it yielded only a minute commercial advantage.

To overcome the limitations imposed by night-time operations, in mid-1923, the Post Office, improving on marines technology developed by General Electric and American Gas Accumulator Company, began to construct the lighted airway. This consisted of a series of electric and acetylene beacons in conjunction with intermediate fields between Cheyenne, Wyoming and Chicago, Illinois. This particular section was chosen because of its relatively flat terrain and proximity to commercial power. Also, more importantly, mail planes leaving New York westbound, could reach Chicago before nightfall, while eastbound departures from San Francisco could land at Cheyenne before dark. Supplementing the beacon system were intermediate landing fields spaced every thirty to fifty miles to provide a safe haven in the event of difficulties. Regular night service began on July 1, 1925[3] and by January 1929 the entire transcontinental route was lighted with the turning on of beacon number 25 at Miriam, Nevada.[4] Westbound flights could now traverse the continent in 34 hours and eastbound services took only 29 hours, besting the railroads by some two days.

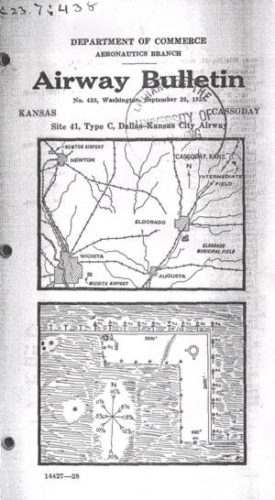

The airways were designed so that no segment exceeded a distance of 1000 miles and were subdivided into 100 miles sections and broken further into ten miles units. In the interest of book keeping, the beacons were numbered based on mileage from a terminal point west to east and south to north with the unit digit dropped.[5] Thus, Medicine Bow, Wyoming, along the SL-O (Salt Lake-Omaha) airway at 325 miles from Salt Lake City, Utah was designated Site 32. Non standard beacon lights, such as acetylene blinkers were given numbers corresponding to their actual mileage from terminal points.[6] The Spring Valley, Wyoming beacon was designated Site 77 on the SL-O Airway which was the actual air mileage from Salt Lake City. In the absence of a nearby town, sites were named after the nearest railroad siding.

Early rotating drum style beacons were twenty-four inch in diameter and installed atop standard 51 foot skeletal steel towers spaced every ten miles. Rotating at six RPM, the drum housed a 24 inch parabolic mirror with two 110 volt, 1000 watt Mazda lamps with one projecting 1,000,000 candlepower and the other serving as a spare.[7] Inside the drum was an automatic lamp changer and should the operating lamp burn out, the defective lamp would be ejected and the spare in place and in focus within a half second. The failure of the first lamp was indicated by the illumination of a red auxiliary red lamp indicating that the beacon had no reserve lamp. Flashing every ten seconds for 1/10th of a second, the high intensity pencil beam had about a 5˚ divergence and was elevated about 1.5˚ above the horizon, aimed to reach the pilot eyes 1000 feet above adjacent beacons.[8] Prisms cast in the exterior lens refracted a small percentage of light upward at 55˚ of the zenith so as to provide close range visibility of the beacon. On clear nights, beacons could be seen at distance of 40 miles.

An illuminated wind indicator was supported on the beacon tower and attached by brackets which allowed it to swivel in any direction. The indicator was of a porous weave fabric colored chrome yellow eight foot long and 18 inches in diameter at the mouth. A 150 watt electric bulb was installed at the mouth with a chrome plated reflector that directed the entire output of the light into the sock. A skeleton metal frame work extended inside for a distance of four feet to hold the sock horizontal, which increased the effective of the lighting.[9]

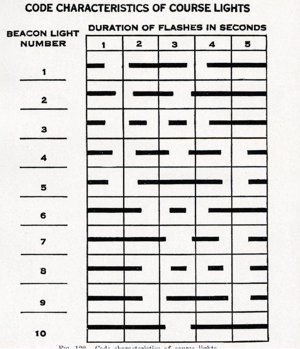

Below the beacon were two course lights mounted on a six foot square maintenance platform, pointing forward and backward along the airway. Each of these lights contained a 500 watt projector lamp with 100,000 candlepower, and were fitted with specially designed mirrors of a cylindro-spherical shape behind an 18 inch doublet lens giving a beam spread of 15˚ horizontal and 8˚ vertical.[10] Equipped with aviation red or green lenses, the course lights would denote the presence of a beacon only (red) or a landing field (green) within two miles of the beacon. By 1934, amber colored lenses were installed at some intermediate fields to denote the presence of an unlighted field or a field that operates lights only at a specified time.[11]Using a system of flashing codes, each course light alternately flashed its characteristic code, while the main beam swung 180˚ opposite. The lens was designed to provide high intensity quick flashes for off airways indications. On course indications were recognized by long flash periods developing full luminous value of the light combined with the color contrast.[12] By observing the coded flash which ran form 1-10 (see figure 1),[13] which corresponded to its mileage along the airway, the pilot determined his position. As the coded flashes were repeated every 100 miles along the airway, the pilot must know which 100 miles segment he is on.

At extremely remote sites without commercial power, beacons were powered by two gasoline generators, one used as a standby and supplied by two 515 gallon fuel tanks. At night or in periods of inclement weather, with the aid of an astronomical clock- or photo-electric cell- a generator would start to crank. If it failed to come online, the standby generator would automatically crank repeating the process until one came online. Generator were thermostatically controlled and would automatically shutdown if they became too hot, or if too cold in freezing temperatures, would automatically start at intervals throughout the day to keep the oil warm.

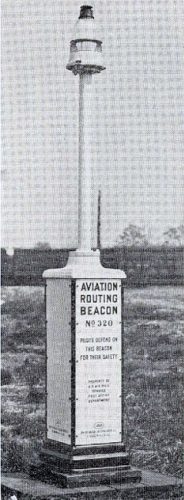

Supplementing the electric course beacon, were 300mm acetylene gas blinkers (see figure 2) manufactured by American Gas Accumulator Company and were spaced every three miles where topography obscured adjacent beacons which flashed 22 times a minute. These were turned off at sunrise and turned on at sunset by a sun valve invented by Gustaf Dalen. The valve consisted of a vertical carbon rod surrounded by three gold plated rods equally spaced and parallel with each other. Morning sunlight reflected from the gilt plated rods caused the vertical carbon rod to expand, cutting off the gas leaving only a small pilot light burning. Evening cooling caused the carbon rod to contract, opening the gas valve allowing the stored acetylene to ignite.[14] The installation of the sun valve reduced acetylene gas consumption by 20-40%. Blinkers were designed to operate unattended for several months and only required occasional cleaning to remove carbon deposits from the burner.

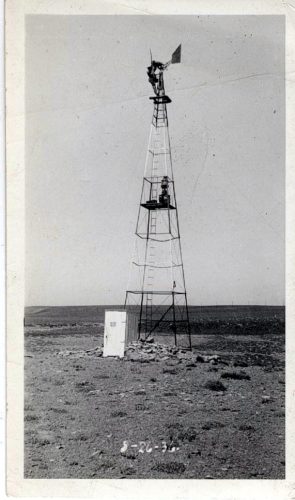

In 1929, the Airways Division of The Department of Commerce began experimenting with wind driven generators (see figure 3) as a power source for airway beacons. The first experiments were conducted on the Atlanta-New York airway with a beacon placed on a 80 foot tower No. 55, sited at Alexandria, Virginia.[15] The wind driven generator supplied a series of storage batteries consisting of two units of 16 cells of 400 ampere-hours. Designated type H beacons, they had an 18 inch double-ended lens which pointed backward and forward along the airway and flashed six times a minute. Above the 18 inch drum was a white light that could be seen from 360˚ and flashed in unison with the range lantern and provided off coursed indications.

Aircraft Year Book

Ben Ashlock Steve Wolff collection

BEACON ABBREVIATIONS FOR VARIOUS INSTALLATIONS[16]

| Symbols | |

| A | Standard rotating beacon with AC power. |

| A Special | Rotating beacon on foreign structure, such as water tank, tall building, etc. |

| B | Standard rotating beacon using DC power generated at the site. |

| BR | Standard rotating beacon using DC power generated at a remote shed and transmitted to the tower by either overhead power line or underground cable. |

| BRA | Standard rotating beacon using AC power generated at a remote shed and transmitted to the tower. |

| C | Intermediate field with B type beacon installed. |

| CA | Intermediate field with standard rotating beacon supplied with AC power generated at the site. |

| D | Intermediate field with standard beacon using AC commercial power. |

| D Special | Type D site with electric code beacon in lieu of rotating beacon. |

| E | An electric code beacon supplied with commercial power. |

| G | An intermediate field with acetylene route beacon and acetylene cabinet blinkers outlining the field boundary. |

| H | Aero-electric beacon (wind driven 32 volt DC power supply). |

| AB | Acetylene blinker light. |

| ARB | Acetylene route beacon or range lantern with 300mm (dia) acetylene blinker installed as an upper 360˚ top light. |

| SL | Side lights consisting of type E beacon with battery operated auxiliary lights. |

Associated with the beacons were ground directional arrows (see figure 4) or day markers consisting of a 54-foot concrete arrow pointing to the next higher numbered beacon and were originally painted chrome yellow with an eight-inch black border. During the night this arrow was lit form above by high intensity lights mounted above on the beacon frame. At the ‘feather’ end of the arrow was a 22 foot by 14 foot power shed housing a Kohler, Westinghouse, or Delco generator if no commercial power was available. On the roof of the power shed was painted the airway route and beacon site number.[17] Between the power shed and arrow was the beacon tower, painted with alternating chrome yellow-and- black bands if in the wooded terrain of the east or red-and-white in the sparse desert regions of the west. By 1932, in the interest of standardization nationwide, red replaced yellow and white replaced black on beacon and radio towers (see figure 5). Arrows where painted red with an eight-inch black border.[18]

Ben Ashlock Steve Wolff collection

The beacon system also comprised a series of intermediate or emergency fields spaced every thirty to fifty miles and at its peak in 1931 offered 385[19] sites throughout the U.S. to airmen in distress. Initially constructed under the auspices of the Bureau of Commerce, Lighthouse Division, intermediate in acreage and plan form depending on terrain and elevation. Land was leased from private owners for periods of 5-10 years and subject to and cost on an average of $4.87 per acre per year nationwide.[20] The average cost of construction of an intermediate field was $1500.[21] Intermediate fields located in mountainous terrain such as Blue Canyon in the California Sierra Nevada’s, had costs running as high as $14,000.00.[22] Field markings included 50 foot diameter white circles at the intersections of runway centerlines with white panels 20 feet long and two feet wide extending from outside the circle along runway center lines to indicate the landing directions.[23] All way landing fields were indicated by a 74 foot diameter circle placed outside and concentric with the standard 50 foot circle (see figure six).

Ben Ashlock Steve Wolff collection

Strict guidelines as to usage were established by the Department of Commerce as to usage by pilots. These were:

(1) Obtain permission from the District Manager, Air Navigation Division, of the district in which the field is located for use of the field commercially.

(1) Obtain permission from the District Manager, Air Navigation Division, of the district in which the field is located for use of the field commercially.

(2) Occasional use of the field for non-commercial use may be made without permission from the District Manager.

(3) Emergency landings, of course require no permission for use of the field.

(4) No field shall be made the permanent base of operation for pilots.

(5) Emergency supplies such as gasoline and oil shall be used only for emergency purposes.[24]

Additional regulations concerning traffic flow were:

(A) The direction of aerial traffic around the outside of the emergency field, shall be counter-clockwise. All traffic flying within 3,000 feet horizontally of the nearest point of the landing area will conform to this circuit rule unless flying at a height in excess of 2,000 feet.

(B) All aircraft approaching the emergency landing filed shall fall in line of traffic and skirt the filed until a point has been reached where a landing can be made (as nearly as surface conditions will permit) into the wind (directly into the wind in case of all-way fields), and if practicable, with a straight glide beginning at least 1000 feet from the leeward edge of the landing area. Contact with the ground shall be effected as near the leeward edge of the landing area as practicable.

(C) Pilots hall circle the field not less than 180˚ before landing. Before landing at night, pilots shall circle the field not less than 270˚.

Exceptions: At an emergency field equipped with radio facilities which permit voice communications with the pilot, a pilot may, upon receiving definitely favorable information regarding wind velocity and filed conditions, make a landing without circling. Such landing should not be made unless the pilot is thoroughly familiar with the field, runways, terrain, obstructions, etc.[25]

Intermediate fields constructed at low altitudes were designed with two strips at right angles to each other approximately 2000 feet long and 200 feet wide with one strip lying in the direction of the prevailing wind (see figure 7). Approximate acreage was 47. In higher elevations (above 4000 feet) the standard length for landing strips was 2500-3000 feet and formed a T, L or X with the inner angles at the junctions of the strips beveled off

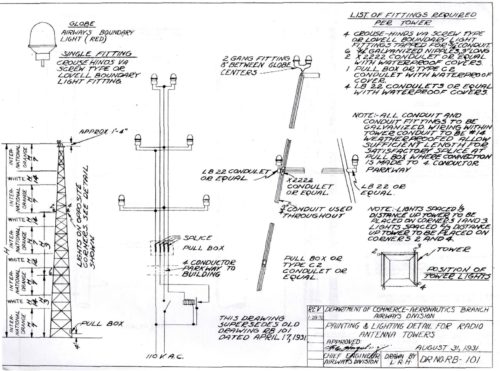

to provide additional landing space for use under strong cross winds.[26] The field boundaries were marked by sheet metal cones 30 inches in diameter at the base and 24 inches in height and painted International Orange with an eight inch white stripe around the middle. In addition special fence-type day markers in 60 foot sections were installed at each interior angle of the landing area and at 600 foot intervals along straight sides.[27] The cones were immediately installed below the clear boundary lights and attached to the boundary light standards. The boundary lights and their associated cones were spaced every 300 feet which enclosed the perimeter of the field and were connected by underground Parkway cable. The lights consisted of waterproof clear prismatic globes and fittings mounted on iron pipe standards 30 inches above ground or higher in the case where snow fall of a greater depth was anticipated. In each light standard, a 15 watt electric bulb was installed if commercial power was available or a ten watt bulb if only the on onsite generator was available.[28] Range lights, similar to boundary lights except that the clear globes replaced green globes, were installed at opposite ends of principle runways to aid pilots in night landings. Two range lights were used at each end of the best or prevailing wind runway, and single lights marked the center lines of other runways. Twenty-five watt red obstruction lights, housed in lighthouse globes were placed at the ends of runways over which approaches and landing to be made. On obstructions in the approach lanes, double obstruction lights were installed and equipped with relays which placed standby lights in operation in case the operating lamps burned out.[29]

Many intermediate fields were staffed on site by Department of Commerce personnel who were fortunate enough to be provided prefabricated accommodations designated as “K” quarters, at a nominal fee. Assistant Airway Keeper, Edwin Crucikshank, who had an annual salary of $1200, was charged $20 per month for his family’s quarters.[30]

Bachelor quarters were fully furnished, while families had to provide their own furnishings. Residences were of wood frame simple in design with Celotex sheathed interior walls and asphalt shingle roofs. Roofs painted in red served as aeroglyphs with the name of the field, airway route, elevation, and site number painted in yellow letters and numbers outlined in black (see figure 8). Although many sites were isolated, personnel often lead idyllic lives. Generous leave schedules, of up to 93 days per annum, 15 days annual leave and 78 days compensatory time for working half days on Saturday and Sundays[31] allowed personnel to take advantage of areas that abounded with fish, game and pristine forests.

Airway Keepers took care of necessary field work, range work, and relief duties which started at 8am and lasted until 5pm. Assistant Airway Keepers stood teletype watches from midnight until noon and noon until midnight.[32] Airway Keepers and Assistant Airway Keepers were required to transcribe 35 words per minute on the teletype circuit which connected all the sites throughout the nation. Information transmitted included hourly weather conditions, planes crossing or PX reports, field conditions and any unusual events.

Betty Jean Crucikshank Steve Wolff collection

During the month of October 1933, a pilot landed his small one passenger plane the Medicine Bow field. The landing was very necessary as the plane was about out of gas from bucking a 55 mile hour headwind, which was plenty gusty. His landing was hurried and the motor shutoff, with a mad dash to one of the wings to attempt to hold his sole possession from kitting out into space. Each gust of wind would lift the plane some ten to fifteen feet into the air and carry it back a hundred feet, until the tail skid would dig into the ground and hold it for a few minutes.

The keeper on duty had noticed the dispatch covering the movement of this ship, as it was destined for a station west, he had been on the look-out for it to pass, but later noticed it landing on the far end of the field. He immediately proceeded in its direction with stakes and ropes. Before reaching the ship he could see the pilot being lifted ship and all into space and carried away about hundred feet where the tail skid would dig into the ground, and bang the pilot back into the ground with no mean consideration. When the keeper arrived the the pilot stated he was about to turn the plane loose, as it seemed that he could hold it no longer, and also seemed hours since he landed. The keeper started to put a stake into the ground and when he turned around for the plane, it moved off another hundred feet and he immediately proceeded to drive the second stake under a wing. It was soon found that this was impossible, and the pilot appearance showed that he was more in favor of his first conclusion, for with both men hanging on to the plane it continued to have its own way and was headed for a crack-up, unless some means could be invented to hold it down.

The second keeper noted the struggle from his home and drove his car to the scene of action, and after some time managed to secure one wing of the ship to the rear bumper of the car. After that the first keeper brought his car and the other wing was attached to its rear bumper, then with a rope from the rear of one car back around the tailskid and to the second car, it was possible to move the small plane to the most favorable place away from the wind and properly stake it down. Not until the following day had the wind receded enough for the pilot to continue on his way, after the plane was gassed and the pilot climbed into his cockpit, waived his adieu, and that’s all.[33]

Crucial to the success of the lighted airway were Department of Commerce Airways Mechanicians who performed scheduled and emergency maintenance. Airway Patrol pilots regularly flew the airways looking for discrepancies such as failed beacons and course lights, improper elevation of beacon lights, malfunctioning radio ranges, poor radio reception and unsafe intermediate field conditions. When found, these were reported to district headquarters where upon an Airway Mechanician was dispatched to the site. In addition to emergency callouts, Airway Mechanicians were responsible for approximately 175 miles of airways and regularly visited each site twice monthly checking power plants, adjusting beacon elevations, removing carbon deposits from acetylene burners, aligning course ranges and insuring the upkeep of intermediate fields.

Beacons were of necessity always located on high points and almost all had difficult access even in ideal conditions. Airway Mechanician and Airmail Pioneer Ben Ashlock and his wife vividly recall in 1930 servicing the White Mountain beacon near Rock Springs, Wyoming in sub-zero weather. Carrying distilled water for batteries, fighting biting winds, they had to make the trip─ nine miles as the crow flies, but a 54 mile trip in their heater-less Model T with its cloth side –curtains with a nine mile walk at the end of the road.[34]

Rotating beacon #1 on Antelope Island and blinker # 2 located on Fremont Island in the Great Salt Lake on the Salt Lake to Pasco airway were normally serviced by boat until the summer of 1934. Severe drought conditions necessitated Airway Mechanician L.P. Rose to service these sites by truck equipped with “airwheels” to negotiate the soft lake bed. Water as much as 18 inches deep in some places prohibited the truck, called the “amphibian” from reaching the blinker at Fremont Island whereupon a local contractor was engaged to supply acetylene gas to the site using a wagon team with the Airway Mechanician accompanying the team driver. Crossing seven miles of lakebed, they used the same route previously used by boat. Darkness over took them by the time they started back and they faced the very real possibility of getting lost the vast blackness of the lake bed or disappearing into a hole; however, as they spotted rotating beacon #3, located at Hooper, Utah on the Salt Lake to Great Falls airway, this made it possible to retrace their previous route without incident.[35]

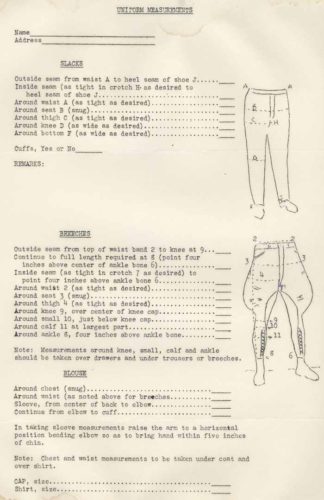

In 1932, there was a brief and unpopular flirtation with requiring airway personnel to wear full uniforms (see figure 9)[36] in addition to the normally required insignia billed cap provided by the airway division. Uniforms were to be purchased by the wearer at their own expense and were quite expensive for the time. A 16oz wool keepers’ uniform with cap and emblem was $17.50 and a tailor made mechanicians’ uniform ran $35.00. Considered gaudy by most standards of dress, the uniforms were facetiously referred to as “lantern lighters” or “wick trimmers” by co-workers.[37] By 1935, the Bureau of Air Commerce issued a directive that no class of Air Navigation employee would be required to adopt a prescribe manner of dress while on duty.[38]

The lighted airways were constructed in every conceivable type of terrain and pushed contemporary technology to its limits. They crossed Georgia swamps, Allegheny mountain tops, and remote western deserts, and were even located along the walls of the Columbia, River Gorge.[39] The beacon system, albeit primitive and hampered by reduced visibilities, laid the ground work for the modern Federal Airway system. ‘Of all American contributions to the technique of air transport operations, Edward P. Warner noted, “[flying at night by beacons] was the greatest. How great it was, and how far it put the United States ahead of the rest of the world, was attested to by the fact that, as late as the early 1930’s, when Americans were flying more or less routinely at night, Europeans were still fingering the hem of the idea of night flying.”[40] In 1923, the U.S. Airmail Service was awarded the prestigious Collier Trophy for its contribution to night flying technology.

Lasting almost 50 years, these luminous sentinels crisscrossed the United States, guiding airmen through a myriad of weather conditions and potentially perilous pathways. The lighted airway reached its zenith in 1941[41] when more than 2000 beacons were in use, the last one being decommissioned in 1972 on Whitewater Hill near Palm Beach, California.[42] By the early 1930’s with the introduction of all metal monoplanes-such as the Boeing Model 247 and the Douglas DC-2 , which were faster, more reliable and along with budget cuts demanded by President Roosevelt economic measures, there was a substantial decrease in the intermediate field network. Intermediate fields were reduced from a high of 385 in 1931 to 250 in 1934. By 1965, only one intermediate field remained in use and was located at Hanksville, Utah.[43]

[1] Barry Rosenberg & Catherine Macaulay, Mavericks of The Sky, (HarperCollins: New York, 2006), 42.

[2] New York Times, May 18, 1918. A1.

[3] Nick A. Kommons, Bonfires to Beacons, (Washington, D.C.: Smithsonian Institution Press 1989), 131.

[4]Domestic Air News, No. 49, (Washington, D.C.: GPO, March 30, 1929).

[5] D.C. Young, Airways Lighting, (Paper to be presented before the Silver Anniversary of The Illuminating Engineering Society, Pittsburgh: October 13-16, 1931), 7.

[6] Ibid., 7.

[7] Ibid., 5.

[8] Ibid., 5.

[9]Air Commerce Bulletin, Vol.1, No. 8.,(Washington, D.C.: GPO, October 15, 1929), 5.

[10] D. C. Young, Airways Lighting, (Paper to be presented before the Silver Anniversary of The Illuminating Engineering Society, Pittsburgh: 13-16, 1931),5.

[11]Air Commerce Bulletin, Vol.6, No.1.,(Washington, D.C.:GPO, July 15, 1934 ), 20.

[12]Air Commerce Bulletin, Vol. 2, No. 2, (Washington, D.C.: GPO, July 15, 1930), 37.

[13] A.K. Lobeck, Airways of America, (The Geographical Press, Columbia University, New York, 1933), 184.

[14]The Sun Valve, http://www.aga.com/web/web2000/com/wppcom.nsf/Pages/History_sunvalve?opendocum. (accessed on September 11. 2007).

[14] S.R. Winters, Wind-Driven Generators for Beacons, (Aero Digest: New York, November, 1929), 109-110.

[16]Notice to Airmen, Form AB-408, (U.S. Department of Commerce, Aeronautics Branch, Airways Division, November 12, 1935), 2-3.

[17] Heister, “Airways”-End of The Seat-of-The-Pants Flying. , 22.

[18]Letter, H.A. Wells to all sites, April 4, 1932, Wolff collection.

[19] William P. Jackson, ed. The Federal Airways System, Intermediate Fields (Institute of Electrical and Electronic Engineers, Inc.,1970),4.

[20]Air Commerce Bulletin, Vol. 1, No.8, (Washington, D.C.: GPO, April 15, 1929), 4.

[21] F.C. Hingsburg, Intermediate Fields, (Aviation, March 15, 1930), 517-518.

[22]Ibid., 517-518.

[23]Air Commerce Bulletin, Vol. 4, No. 9, (Washington, D.C.: GPO, November 1, 1932), 218.

[24]Notice to Airmen, Form AB-408,No. 5-10, (U.S. Department of Commerce, Aeronautics Branch , Airways Division, Washington, D.C.: GPO, August 1,1935), 3., Wolff collection.

[25]Notice to Airmen, Form AB-408, No. 5-11, (U.S. Department of Commerce, Aeronautics Branch, Airways Division, Washington, D.C.:GPO. August 16,1935),5, Wolff collection.

[26]Air Commerce Bulletin, Vol. 1, No. 8, (Washington, D.C.: GPO, October 15,1929),3.

[27]Air Commerce Bulletin, Vol.4, No.9., (Washington, D.C.: GPO, November 1,1932),219.

[28]Ibid., 219.

[29]Air Commerce Bulletin, Vol.4, No.9., (Washington, D.C.: GPO, November 1, 1932),219.

[30] Betty Jean Crucikshank Cole-Keller, (Hudsonville, MI, Self published, Edwin Crucikshank,Airways Keeper Site 32, Medicine Bow, Wyoming, 2007),3.

[31] W.E. Kline to All Airway Keepers and Assistant Airway Keepers, June, 1933, Wolff collection.

[32] W.E. Kline to All Airway Keepers and Assistant Airway Keepers, June 24, 1932, Wolff collection.

[33] Karl G. Schowe, Along the Airways, Air Commerce Bulletin, Vol.5, No10, (Washington, D.C.:GPO, April 15, 1934), 261.

[34] Dick White, Editor, Rawlins Daily Times, January 28, 1950.

[35] W.T. Miller, Chief, Airways Patrol Pilot, Along the Airways, Air Commerce Bulletin, Vol.6, No.4, (Washington, D.C.: GPO, October 15, 1934), 99.

[36] Steve Wolff, Collection.

[37] Heister, “Airways”-End of The Seat-of-The Pants Flying., 128.

[38]Ibid,. 135.

[39]Air Commerce Bulletin, Vol.2, No.17, (Washington D.C.: GPO, March 2, 1931),439.

[40] Edward P. Warner, Early History of Air Transportation,(York:Pennsylvania,1937),26-28.

[41] Jackson, ed., The Federal Airways System, Intermediate Fields., 4.

[42] Larry Cheskaty, FAA Aviation News, (Oklahoma City: 1977),18-19.

[43] Jackson, ed., The Federal Airways System, Intermediate Fields., 6.